The economic benefit of using the BMS system

The economic benefit is achieved in significant savings that occur every year if the system is managed professionally from several aspects:

►

Saving electricity

BMS programs operate each piece of equipment only as needed, in addition to balancing loads on different equipment to prevent damage from overloading

Air conditioning, for example, must be adjusted to the air conditioners' operating schedules every week or two during the spring and fall to change according to the temperature outside.

The system also automatically operates a suitable number of air conditioners according to the expected thermal load. In the early morning, for example, only a few air conditioners. The number of air conditioners increases over time during the day, then gradually decreases as the temperature drops in the evening.

Another example: ventilation and suction fans in parking lots

The optimal time for operating pumping fans is when the air outside is at relatively low temperatures after midnight, outside working hours. Operating them during periods of high temperatures should be avoided, especially if the car exhaust rate is small. In contrast, the operation of suction fans should be synchronized with peak traffic periods in parking lots.

This way, electricity is saved, equipment wear is greatly reduced, and the environment for people who visit the building is improved.

►

Saving technicians' time

The BMS system doesn't need specialized staff to constantly monitor it status as is common. The system operates in an automated manner programmed by its engineers. This way, maintenance technicians' time is saved. They are notified of faults periodically every (1-4) days to work on solving them if found.

►

Recognizing faults or signs of faults immediately after they occur reduces the cost of repairing them

For example, when a Freon leak occurs in an air conditioner, the cost of recharging it is much less than if the leak went unnoticed for some time. That would lead to the complete damage of the compressor, which is much more expensive than Freon.

►

Ensuring the readiness of critical systems, such as Fire Fighting systems.

It's common for maintenance team members to put these systems in manual operation mode when performing routine maintenance work, then forget about them in this mode. This causes the systems to not start up automatically when needed.

►

Evaluating the performance of maintenance teams through the BMS system

The system allows monitoring recurring malfunctions, which are usually reported to the management, as they may arise from the equipment being overloaded or due to deficiencies by the maintenance personnel in charge of it. The management can then take what it deems appropriate regarding them.

How to get the most out of the BMS system?

” الاستخدام الأمثل لنظام (بي .إم . اس) لا يتطلب وجود مشغل بصورة دائمة أمام حاسوب النظام “

Like any other system, the maximum benefit from the "BMS" system is achieved by employing its full technical capabilities.

This is done in two steps:

First: Employing the existing system to the maximum extent. This is achieved by setting operating schedules for the systems under it to achieve maximum savings in electricity consumption and reduce their operating hours to a minimum.

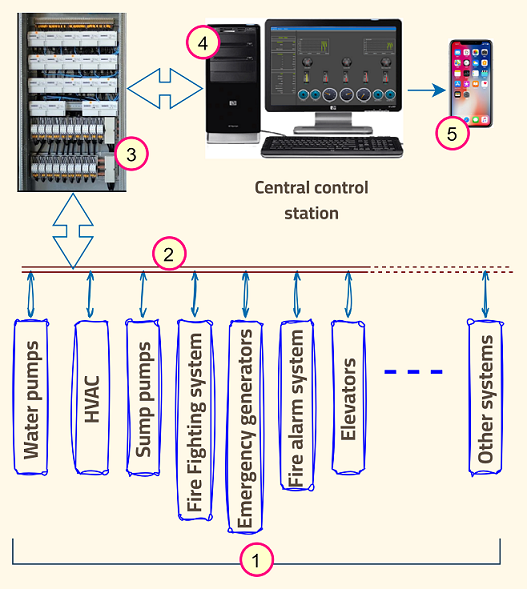

Also, the system’s status is monitored through the alarms issued by the equipment to diagnose existing or expected faults and direct maintenance teams or contractors accordingly.

Second: Designing and implementing solutions to recurring system problems.

Let's give an example of what is meant by solving recurring problems. One common mistake in designing water pumping systems (booster pumps) is not monitoring the pressure in the tank. When there is a constant air leak in these tanks, this causes the pumps to rapidly turn on and off, leading to their damage. The solution in this case is to install sensors on the pressure tanks to measure the air pressure inside them and connect them to the BMS system to send an alert when the pressure drops below a certain limit early so that the maintenance team can restore its pressure.

Another common problem is in pump rooms, which are often located underground and out of sight. Water may accumulate on the floor and cause the pumps and the other equipment to become rusty.

The (general) solution in this case is to place electronic water sensors in specific locations and then connect them to the BMS system to alert as soon as water begins to accumulate. Notifications can also be sent to maintenance officials through their mobile phones.